I recently came across a superb, excellent modern refrigeration technology option, which is based in Brno, Czechia (or Czech Republic if you like). First of all, check out the incredible products on the brand’s own website – Mirai Intex. Once you get an understanding of what the company’s innovative products are all about, delve deeper and enhance your life. Here is an overview of Mirai Intex.

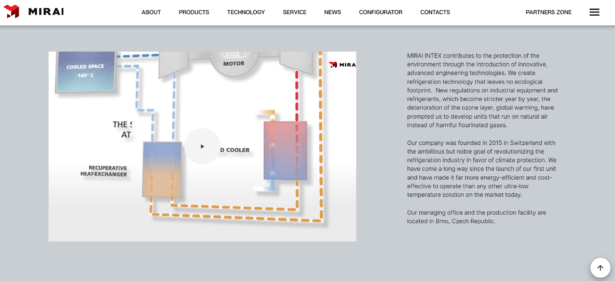

MIRAI INTEX is dedicated to environmental conservation by employing cutting-edge engineering technologies. They specialize in refrigeration solutions that have zero ecological impact. Increasingly stringent regulations on industrial equipment and refrigerants, coupled with concerns over ozone layer depletion and global warming, have driven the company to develop units that utilize natural air instead of harmful fluorinated gases.

Established in 2015 in Switzerland and now with an HQ in Czechia, the company aimed to revolutionize the refrigeration industry in support of climate preservation. Since the inception of their first unit, they have significantly enhanced its energy efficiency and cost-effectiveness, making it the most efficient ultra-low temperature solution available today.

The distinguishing feature of Mirai Intex lies in their internal research and production of their turbo-compressor equipment, which forms the foundation for crafting the most eco-conscious refrigeration machines for ultra-low temperature needs.

The applications of their refrigeration technology span from preserving biomedical and food items to climate testing, gas liquefaction, and cooling chemical processes. Leveraging their broad expertise across diverse domains, we excel in crafting customized solutions for their partners, offering comprehensive services ranging from product development to production capabilities.

Their vision is that they aim to provide the refrigeration industry with sustainable green technology to mitigate human impact on the environment. Through their ongoing revolutionary groundbreaking air cycle technology, they strive to elevate your production processes to an environmentally friendly standard.

MIRAI technology, aligned with the COP21 Paris Agreement, presents a practical alternative to chemical refrigerants, contributing to environmental preservation by curbing harmful emissions and greenhouse gases.

MIRAI products exclusively utilize natural refrigerant – pure air. Say goodbye to concerns about refrigerant leakage and potential non-compliance with evolving regulations.

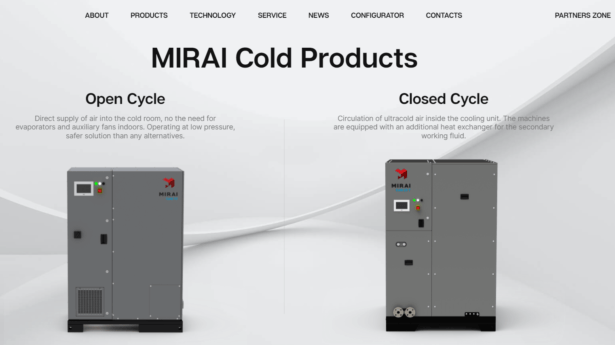

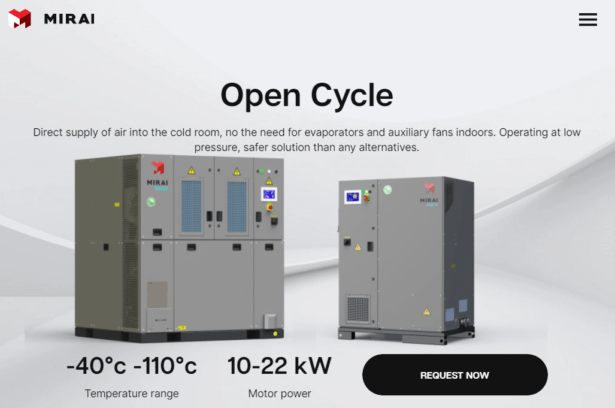

The Mirai Cilkd products have two cycles, as listed here –

Mirai Intex Use of Air Cycle Technology

Mirai Intex makes use of what is known as Air Cycle Technology. The air cycle finds extensive application in air separation plants for achieving cryogenic cold, liquefying natural gas, and powering aircraft air conditioning systems. In their refrigeration machine production, the company is harnessing the potential of the air cycle. At the core of this system lies the turbo-module unit, meticulously developed and produced in-house to ensure optimal efficiency and reliability.

This technology exploits air’s ability to heat up during compression and cool down during expansion. By iteratively cycling through compression and expansion phases, ultra-low temperatures as low as -160°C can be attained and sustained.

So what are you waiting for? Embrace this excellent new technology as it’s making its way up into the hall of fame – get in fast before everyone else jumps on the bandwagon!